Liquid Ring Vacuum Pumps

Description

Liquid Ring Vacuum Pumps

Circutec Australia is the official liquid ring vacuum pump supplier and distributor for Circutec in Australia and New Zealand. Circutec Australia is a subsidiary of Circutec (formerly Speck Pumps) of Roth, Germany who are high quality manufacturers of liquid ring vacuum pumps. Buy liquid ring vacuum pump – For sale at Circutec Australia.

Circutec liquid ring value pumps are are high-quality, reliable pumps. For decades now, Circutec has been developing and manufacturing liquid ring vacuum pumps and has made a name for itself with its innovative, industry-specific advances in this field. High quality, reliable with a wide variety of graded pump sizes. Circutec Liquid Ring Vacuum Pumps are suitable for a wide range of industrial applications. Circutec offers a broad portfolio of differing robust designs, including those suitable for handling large amounts of water and condensation, water saving versions, low noise pumps, industrial vacuum pumps, liquid ring pumps, and two-stage versions.

Liquid Ring Vacuum Pump Advantages

- High-quality, reliable liquid ring vaccum pumps which are suitable for many industrial applications.

- Great variety of graded pump sizes which span a large range of delivery volumes

- Broad portfolio of different designs: Robust standard designs, pumps that are free of dead space, pumps suitable for delivery of water shares, operating water-saving pumps and low-noise, two-stage pumps

Liquid Ring Vacuum Pump Areas of application

- They are used in many sectors in discontinuous and continuous operation in the three basic processes of extraction, leakage extraction and degasification, for example:

extracting dry gases, saturated gases and vapours

extracting contaminated gases

delivering liquid shares at a constant vacuum

delivering explosive gases, e.g. hydrogen - Oil-free compression, i.e. no oil in the medium nor in the exhaust air

- Minimum suction pressures possible up to 33 mbar abs., with gas ejectors (also known simply as “ejectors”) even possible up to 5 mbar abs.

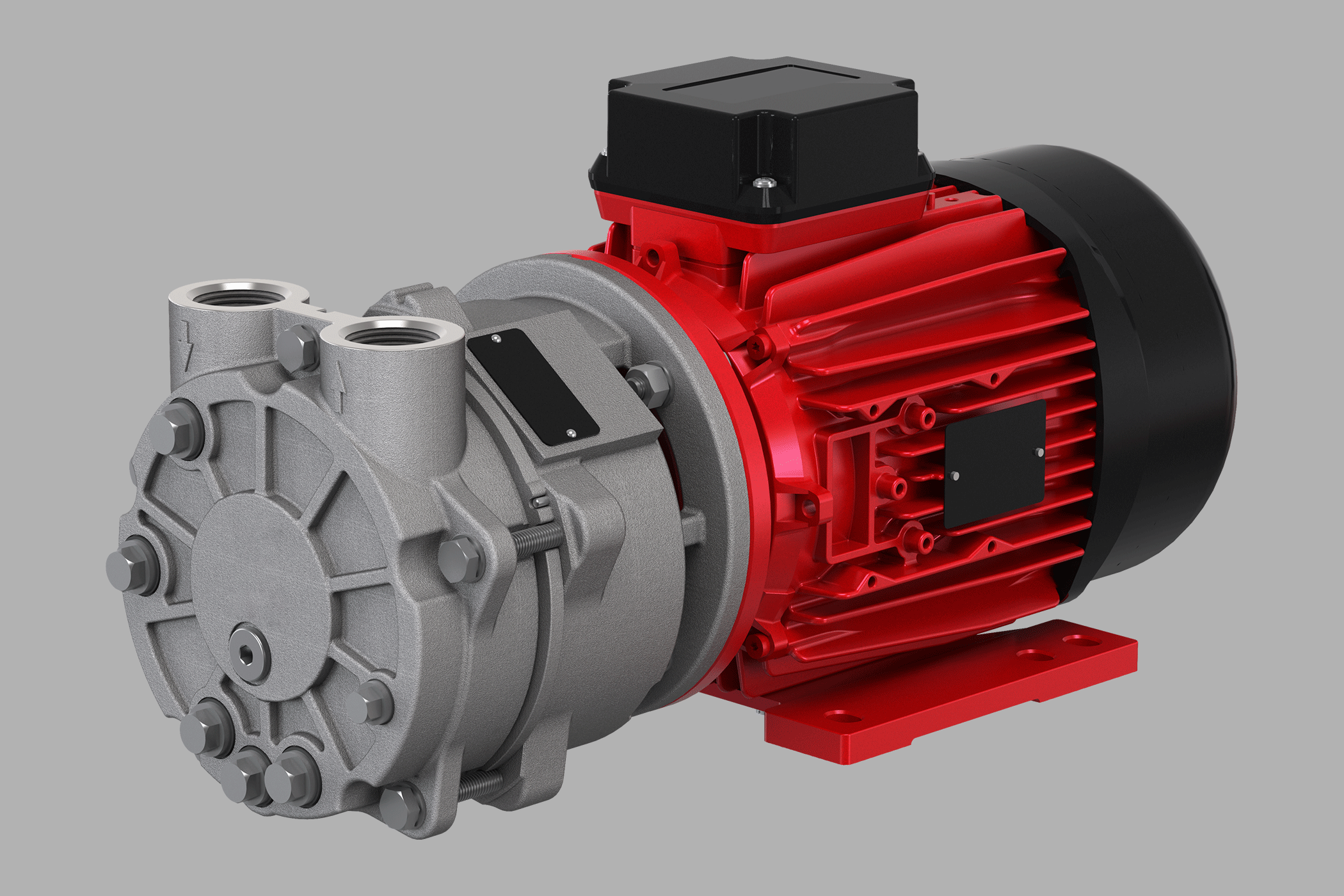

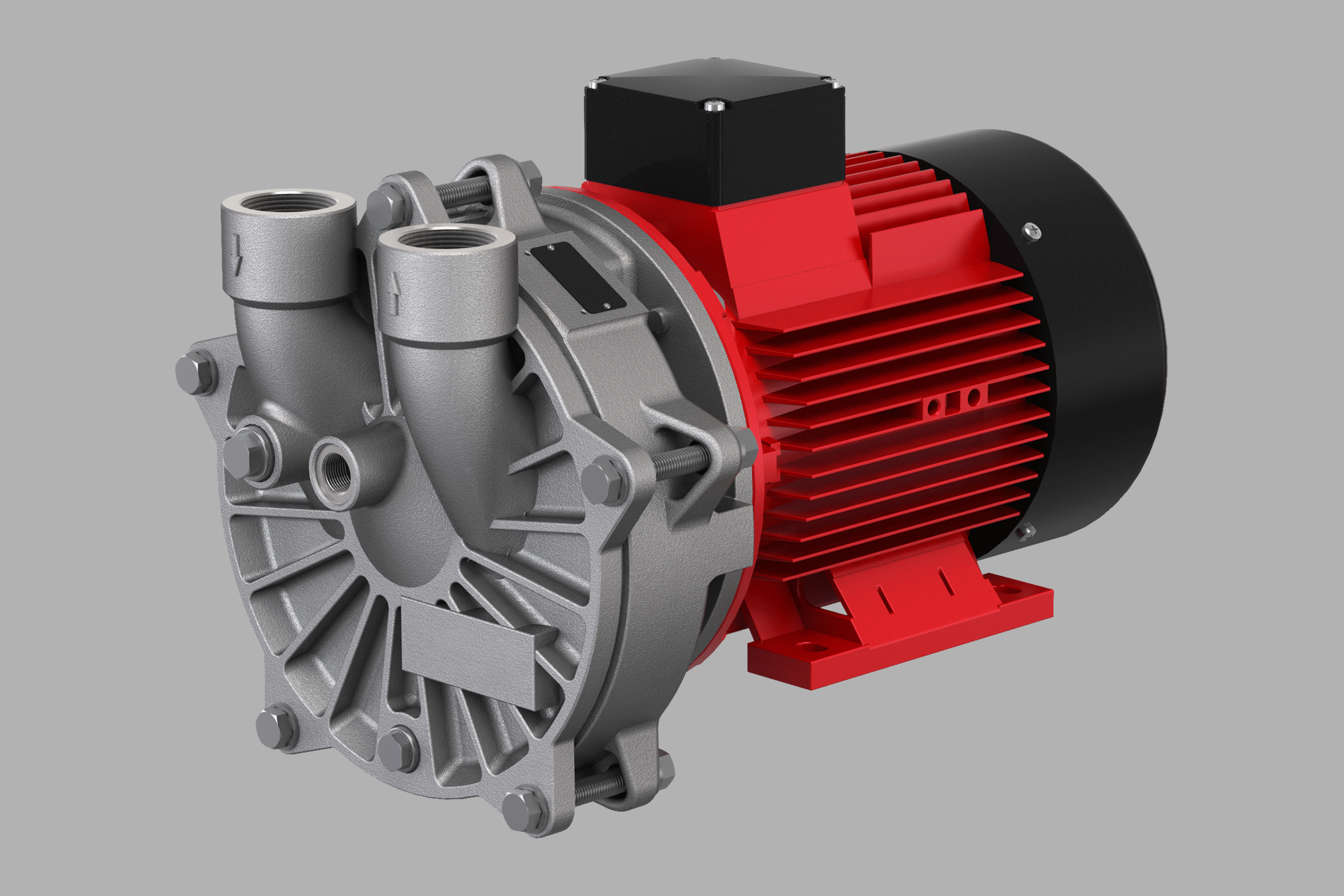

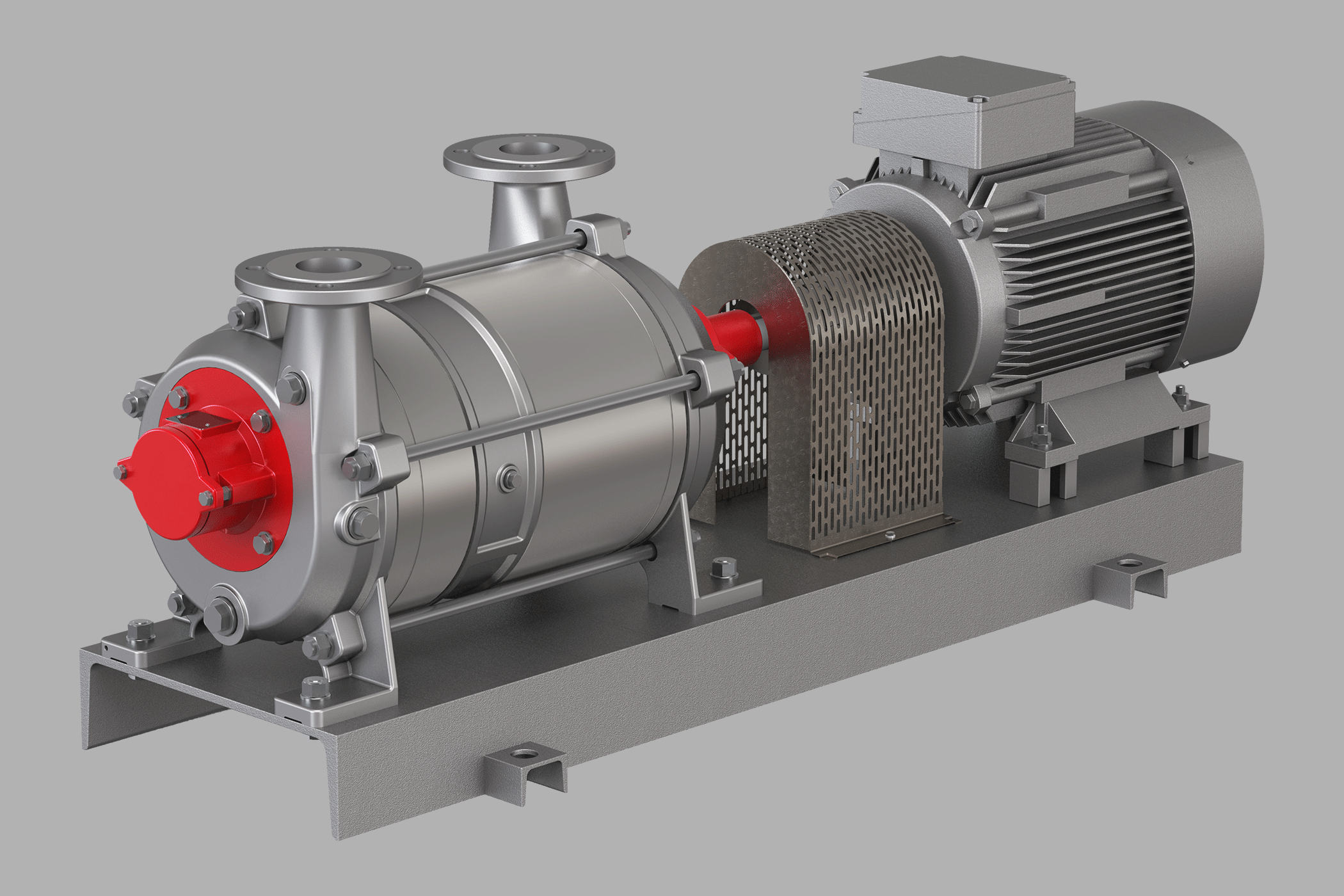

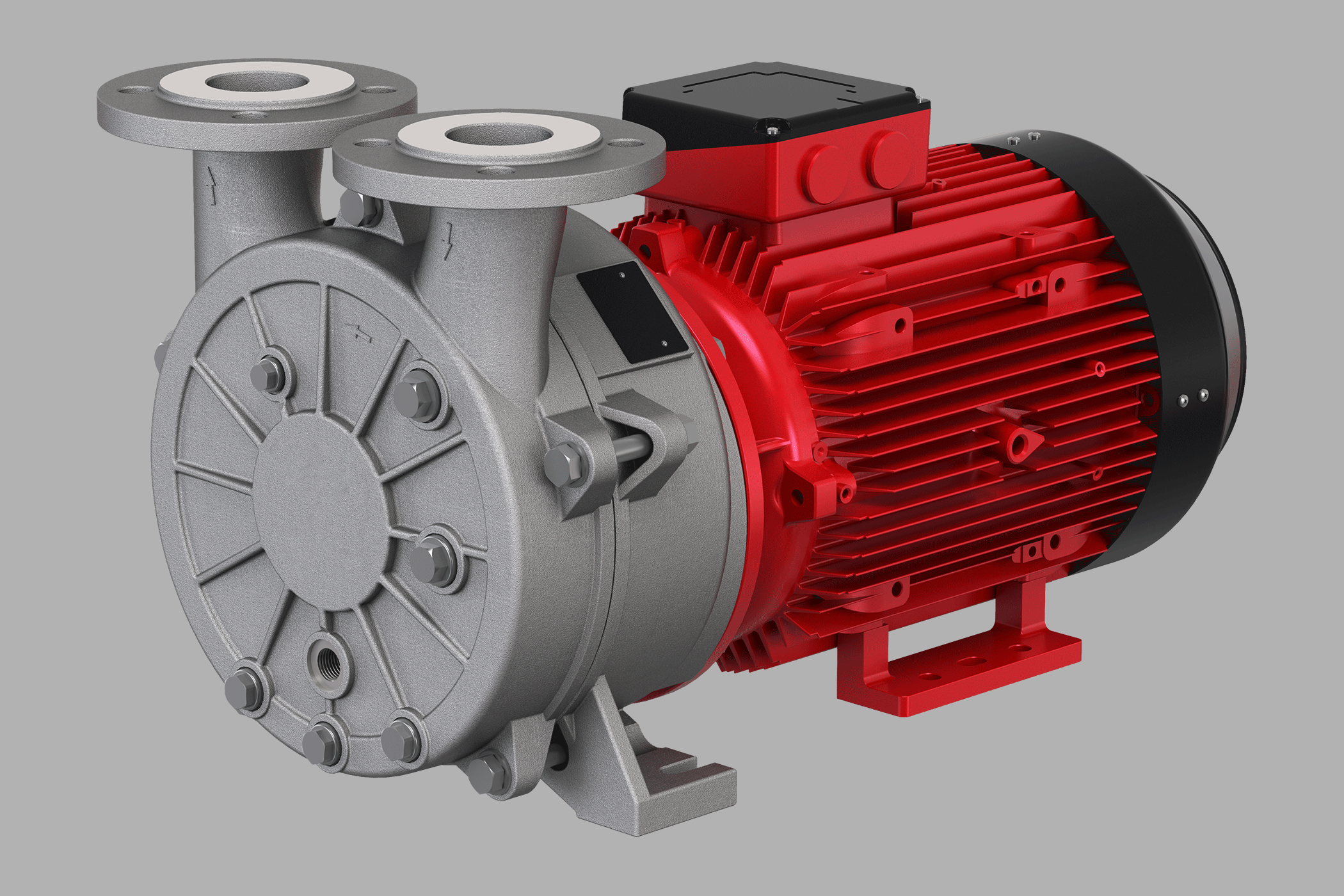

VI-30

Water savers with internal water restraining system

ISO

50 Hz: max. 33 mbar abs. / 45 m³/h

60 Hz: max. 33 mbar abs. / 55 m³/h

US

50 Hz: max. 1 inch Hg a / 26 CFM

60 Hz: max. 1 inch Hg a / 32 CFM

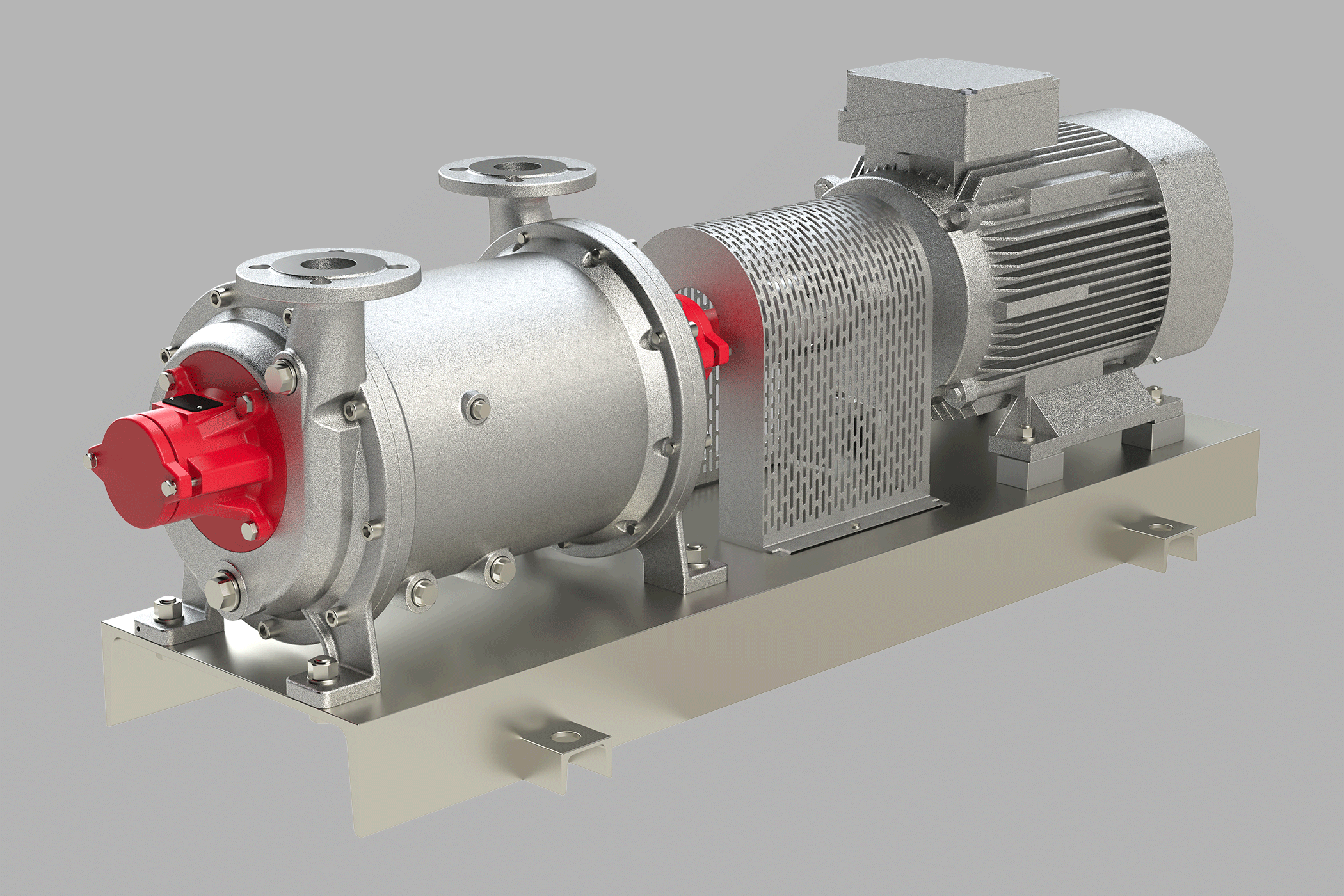

V-55

The All-rounders

ISO

50 Hz: max. 33 mbar abs. / 370 m³/h

60 Hz: max. 33 mbar abs. / 445 m³/h

US

50 Hz: max. 1 inch Hg a / 218 CFM

60 Hz: max. 1 inch Hg a / 262 CFM

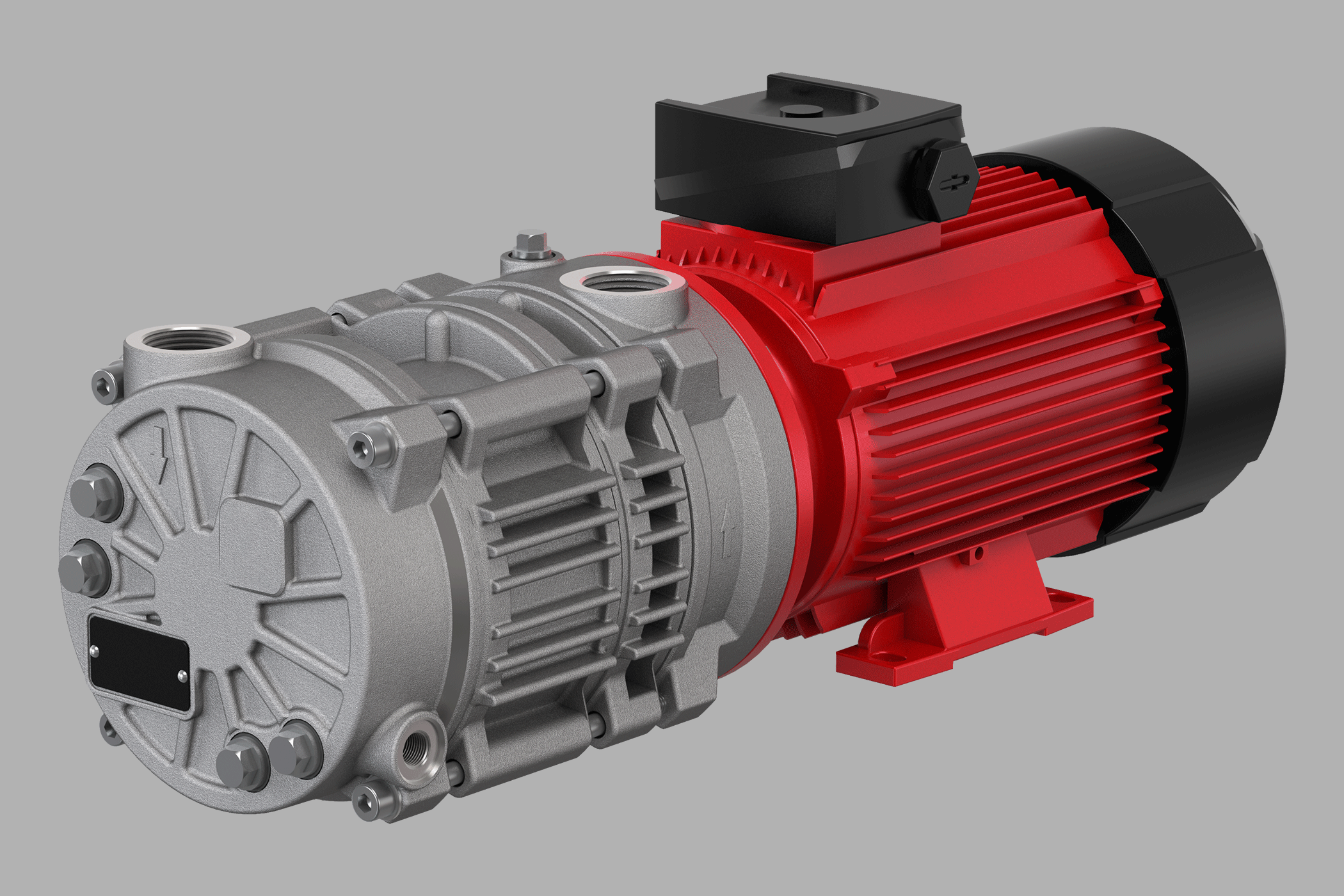

VG-95

Valveless & low-maintenance

ISO

50 Hz: max. 40 mbar abs. / 203 m³/h

60 Hz: max. 40 mbar abs. / 245 m³/h

US

50 Hz: max. 1 inch Hg a / 119 CFM

60 Hz: max. 1 inch Hg a / 144 CFM

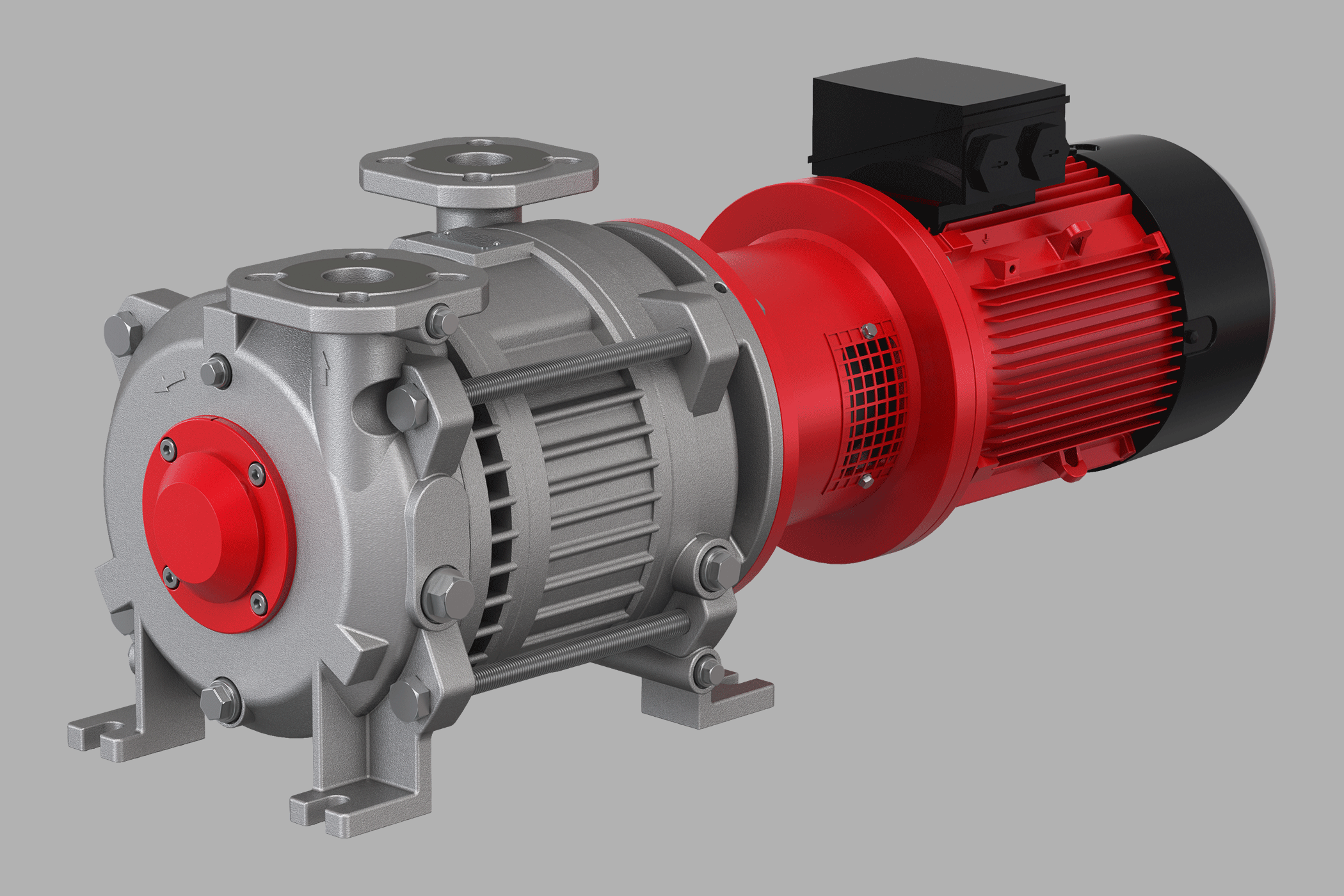

VN-95

For large quantities of additional liquid

ISO

50 Hz: max. 55 mbar abs. / 180 m³/h

60 Hz: max. 55 mbar abs. / 215 m³/h

US

50 Hz: max. 2 inch Hg a / 106 CFM

60 Hz: max. 2 inch Hg a / 127 CFM

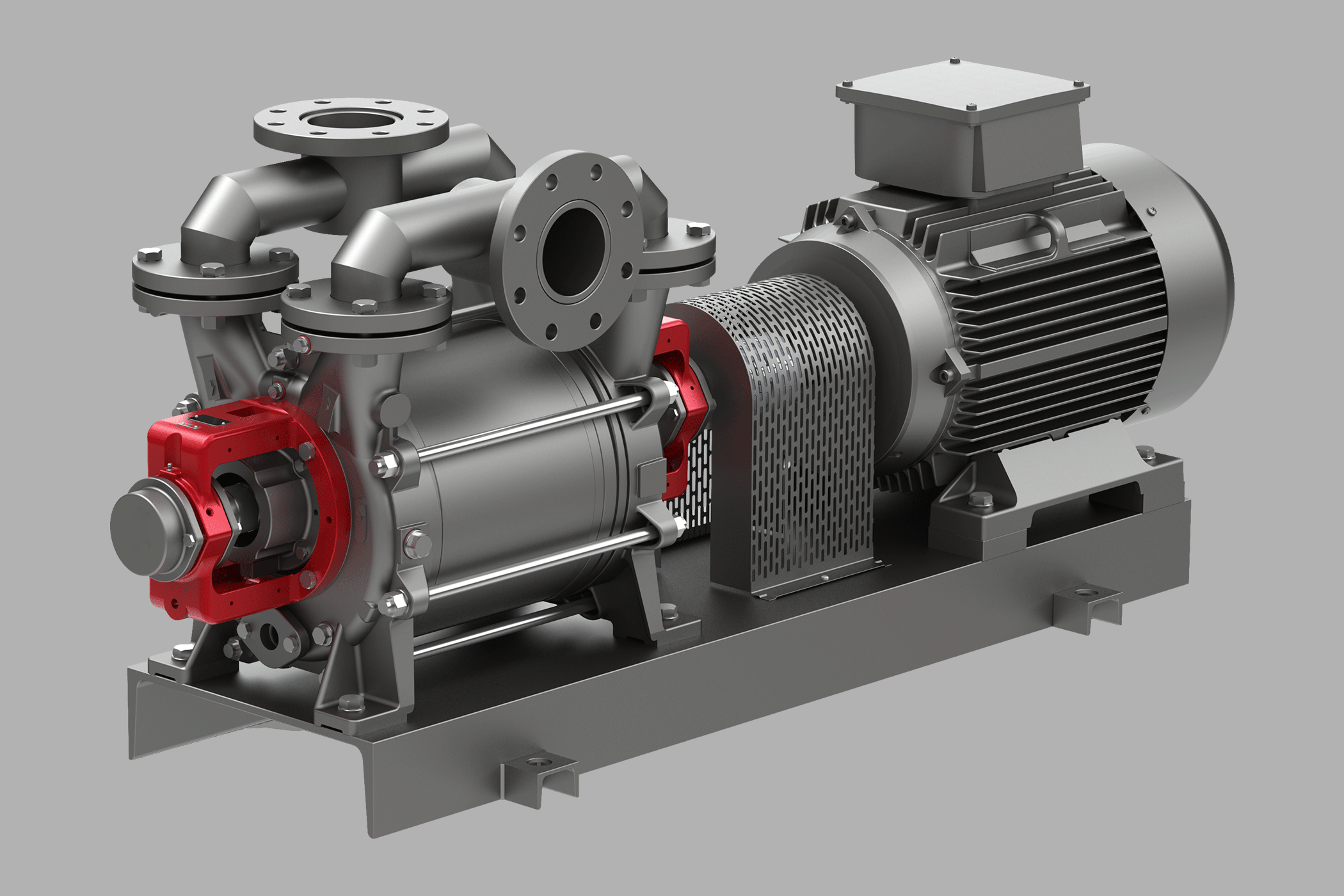

VU0600

Tried-and tested robust technology

for rough vacuum ranges

ISO

50 Hz: max.120 mbar abs. / 1550 m³/h

60 Hz: max. 120 mbar abs. / 1900 m³/h

US

50 Hz: max. 4 inch Hg a / 912 CFM

60 Hz: max. 4 inch Hg a / 1118 CFM

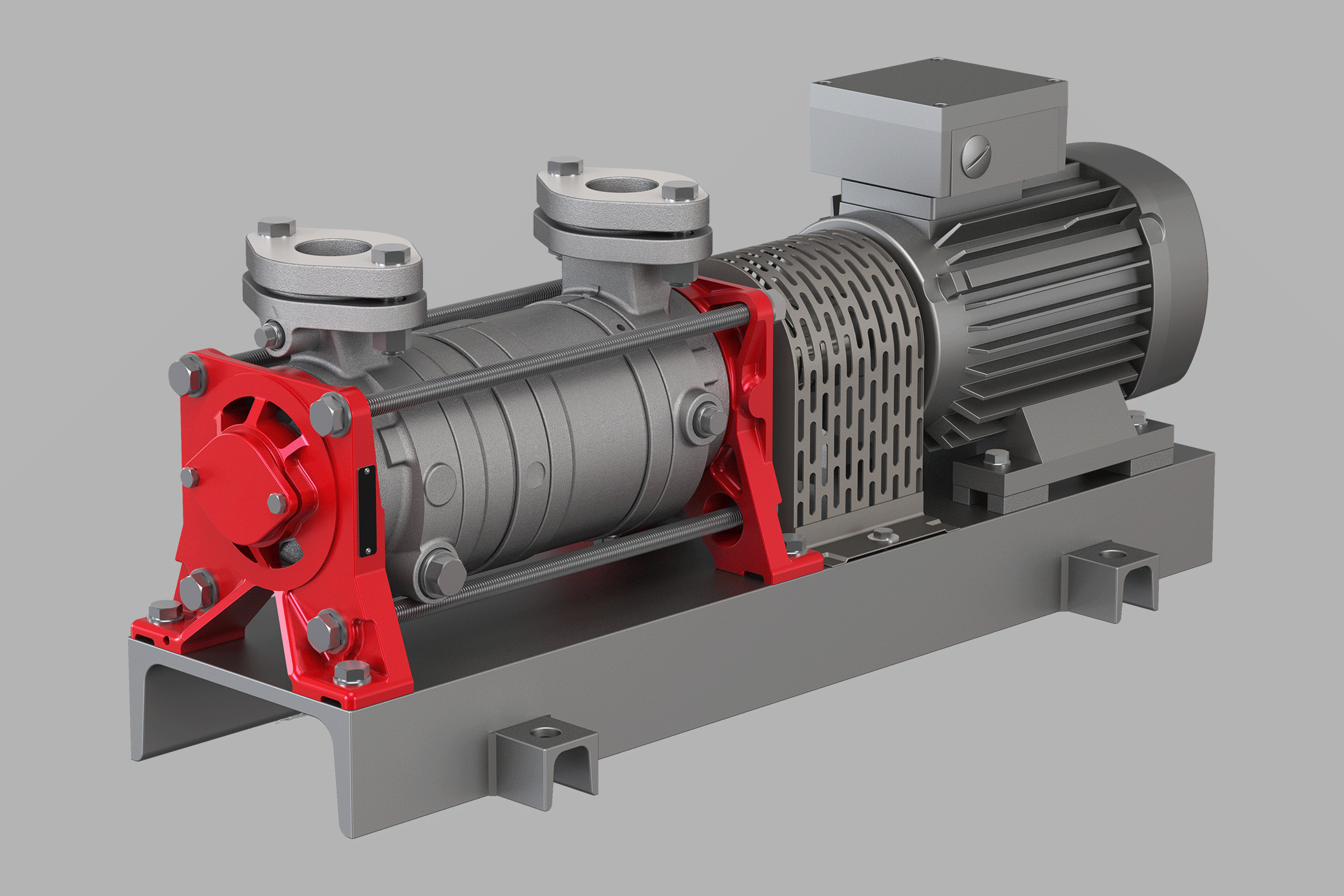

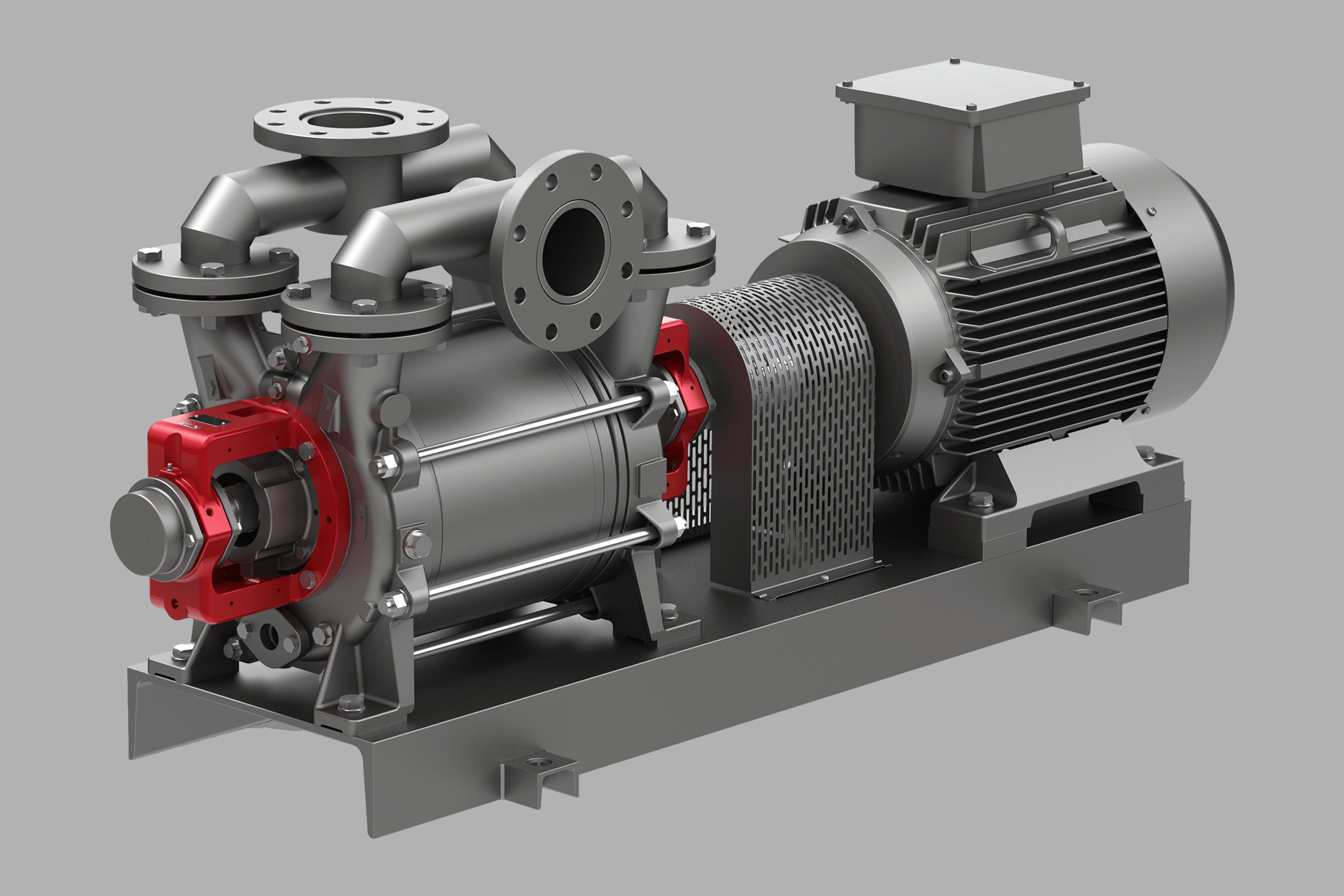

VH0040

Tried-and tested robust technology

for deep vacuum ranges

ISO

50 Hz: max. 33 mbar abs. / 56 m³/h

60 Hz: max. 33 mbar abs. / 68 m³/h

US

50 Hz: max. 1 inch Hg a / 33 CFM

60 Hz: max. 1 inch Hg a / 40 CFM

VHC0500

Innovative technology for deep vacuum ranges

ISO

50 Hz: max. 33 mbar abs. / 1600 m³/h

60 Hz: max. 33 mbar abs. / 1700 m³/h

US

50 Hz: max. 1 inch Hg a / 940 CFM

60 Hz: max. 1 inch Hg a / 1000 CFM

VZ-50

Robust and low noise technology

for deep vacuum ranges

ISO

50 Hz: max. 33 mbar abs. / 185 m³/h

60 Hz: max. 33 mbar abs. / 225 m³/h

US

50 Hz: max. 1 inch Hg a / 109 CFM

60 Hz: max. 1 inch Hg a / 132 CFM

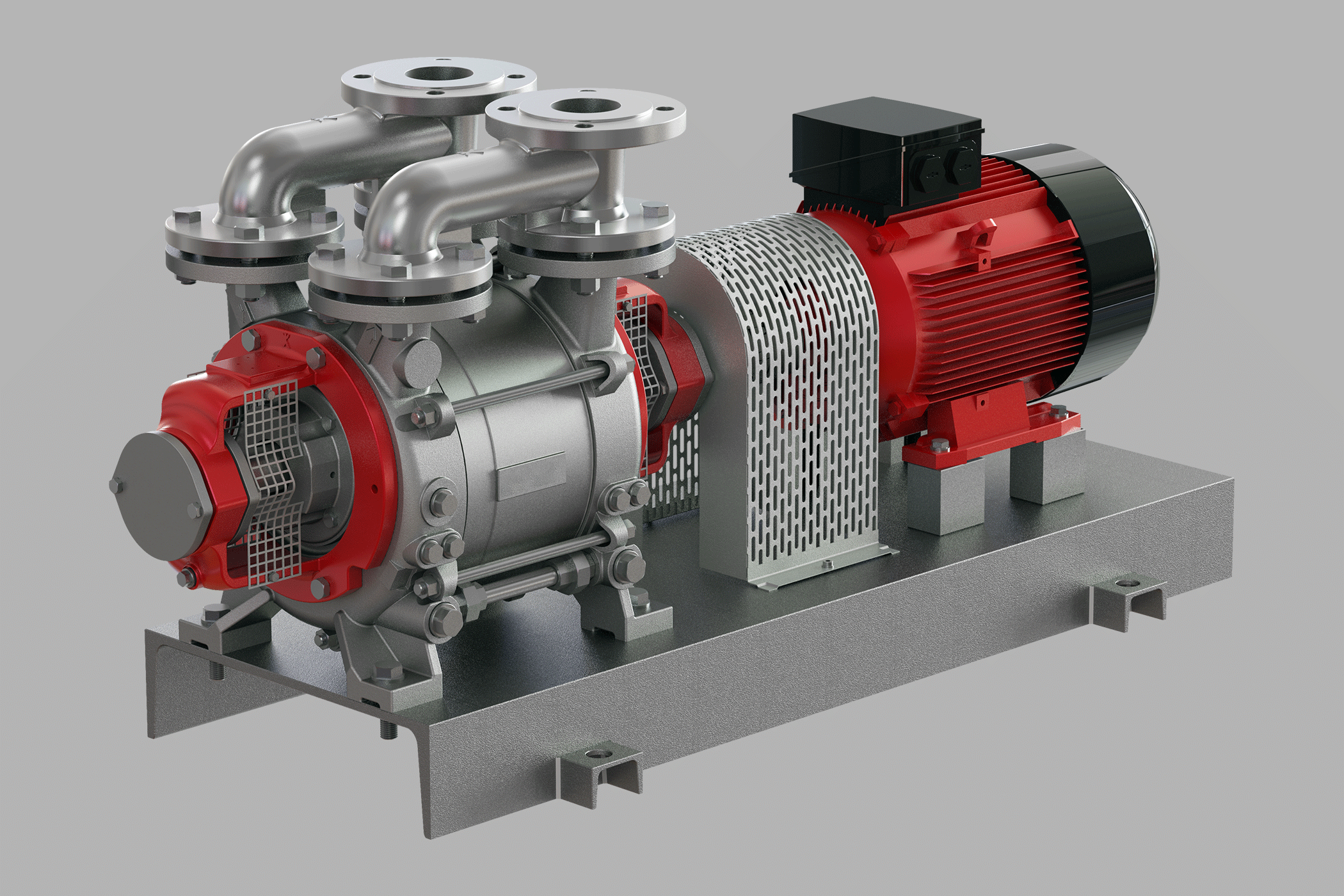

VZ0110–VZ0180

Durable, quiet-running technology

for a lower vacuum

ISO

50 Hz: max. 33–800 mbar/ 55.0–186.0 m³/h

60 Hz: max. 33–800 mbar/ 65.0–223.0 m³/h

US

60 Hz: max. 1.0–23.6 inHg / 38.3–131.3 CFM

VU0600

Durable, tried-and-tested technology

for low vacuums

ISO

50 Hz: max. 120–800 mbar/ 8.0–1552.0 m³/h

60 Hz: max. 120–800 mbar/ 9.0–1900.0 m³/h

US

60 Hz: max. 3.5–23.6 inHg/5.3–1118.3 CFM

VE

VE series

For suction and compressor operation

ISO

50 Hz: max. 33–800 mbar/ 18.0–190.0 m³/h

60 Hz: max. 33–800 mbar/ 16.0–235.0 m³/h

US

60 Hz: max. 1.0–23.6 inHg/ 9.4–138.3 CFM

VHD

Innovative technology

for a lower vacuum with high compressive strength

ISO

50 Hz: max. 33–800 mbar/ 150.0–620.0 m³/h

60 Hz: max. 33–800 mbar/ 180.0–740.0 m³/h

US

60 Hz: max. 1.0–23.6 inHg/ 105.9–435.5 CFM

VU0351

Durable, tried-and-tested technology

for a lower vacuum

ISO

50 Hz: max. 33–800 mbar/ 110.0–425.0 m³/h

60 Hz: max. 33–800 mbar/ 130.0–490.0 m³/h

US

60 Hz: max. 1.0–23.6 inHg / 76.5–288.4 CFM

Liquid Ring Vacuum Pump Design

Circutec are vacuum pump suppliers that offer both single stage and two stage pumps with and without flap valves, with close-coupled and base plate versions. We engineer our mechanical seals to suit the demands of specific applications where requested, and can provide a double acting seal when required. Certail models, such as our VZ Series are also available with magnetic drive, allieviating the need for a mechanical seal altogether. Circutec offers various build materials such as Copper Alloy Cast Iron and Stainless Steel. Our base plate versions come with the option of material certificates, examination certificates and ATEX II IG IIB+H2 cbk TX, and the close coupled versions with ATEX II 2G cb TX

- Single-stage and two-stage pumps, with and without flap valves

- Close-coupled pumps and base plate pumps

- Mechanical seals, depending on the medium

- Usually with a single mechanical seal, but also available with a double-acting mechanical seal

- VZ model series also with a magnetic coupling

- Various material designs: Copper alloy, grey cast iron and stainless steel

- Base plate pumps with type examination certificate and ATEX (II 1G IIB+H2 cbk TX)

- Close-coupled pumps with ATEX II 2G cb TX