Vacuum Pumps

Industrial Vacuum Pumps

SpeckAustralia.com is the official vacuum pumps supplier and distributor for Speck in Australia and New Zealand. Speck Australia is a subsidiary of Speck Pumps of Roth, Germany who are high quality manufacturers of vacuum pumps. Buy Vacuum Pumps – For Sale in Australia SpeckAustralia.com

Where the use of a liquid ring industrial vacuum pump is impractical or unwarranted, self-contained dry-running or high vacuum oil-flooded Speck vacuum pumps are the instrument of choice for many vacuum applications.

The SV Series features a high ultimate vacuum pump (less than 0.5 mbar) with relatively quiet operation (66 dB A). A versatile unit used extensively in packaging and drying amongst many other applications.

2XZ series direct-driven rotary vane vacuum pumps are one of the main industrial vacuum types used for pumping gas from sealed containers. It not only can be used alone but also as a backing pump for booster pumps, diffusion pumps, turbo molecular pumps and titanium pumps. Commonly used for electric vacuum device manufacturing, thermos manufacturing, vacuum welding, printing, plastic, refrigeration equipment repairs and instrument repair.

LG series dry screw vacuum pumps can manage both condensable vapours and some solids with no residue. They offer a number of advantages over traditional industrial vacuum pump designs. As there is no oil or water in contact with the process vapours, they are considered an environmentally friendly choice for chemical & pharmaceutical processing, solvent recovery, crystallization, vapour coating, petroleum and semiconductor markets.

Product groups

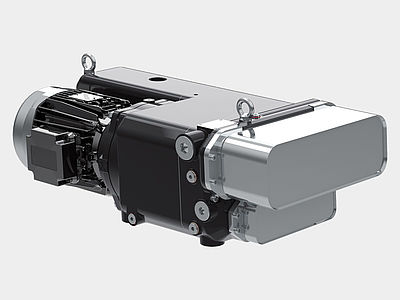

BluSystems

Advantages

- Ready-to-connect modular system – developed for wet and dry calibration of plastic profiles

- Also suitable for condensate recovery

- Very high energy savings thanks to demand-driven vacuum generation

- Decentralised vacuum units with smart regulation and simple operation

- Can be retrofitted – simple installation in the place of existing vacuum pumps

- Automatic regulation and saving of parameters enables reproducible, consistently high quality of the end products

Description

- Vacuum units comprising liquid ring vacuum pumps, motors with frequency converter, sensors and operating unit

- BluVacCompact also with integrated separator tank for extracting air/water mixtures

- BluVacD (BluVacDecentralised) for existing separator tanks/vacuum tanks in the system

- BluLine VB based on a side channel blower

- Control using standard operating panel or via PLC interface

UniVac

Advantages

- Plug-and-play vacuum units which are mechanically ready to connect – developed for sterilisers

- Also for other applications such as degasification, drying and distilling

- Extremely compact, completely pre-assembled and easy to maintain

- Highly effective two-stage separator tank

Description

- Vacuum units comprising liquid ring vacuum pumps, separator tank, condenser and optional heat exchanger

- Integration of additional components such as gas ejectors, valve technology or exhaust gas condenser upon request

- UniVac-…-1 with robust, single-stage vacuum pumps from model series V

- UniVac-…-2 with quiet, two-stage vacuum pumps from model series VZ

- Material design in grey cast iron (UniVac-10-1 in copper alloy)

Vacuum Systems

Advantages

- Prefabricated system solutions offer many advantages – both for the manufacturer of the units and plant operators

- Just one single supplier for a system solution instead of many suppliers for various components

- Compact vacuum units with low space requirements/with small dimensions

- Reduction in assembly time for the customer thanks to plug-and-play vacuum units which are mechanically ready to connect

- Also the possibility of retrofitting present devices and systems, depending on the design in question

- Speck ensures the best possible integration of components such as separator tanks, condensers, valve technology, gas ejectors, exhaust gas condensers, sensors, frequency converters and regulation/control systems.

- Speck undertakes all work steps on behalf of the customer – from the development to the manufacture and the final inspection – with cutting-edge and highly advanced test rigs.

Design

- BluSystems – vacuum units for wet and dry calibration of plastic profiles

Huge energy savings thanks to frequency regulation and a smart system solution - UniVac – plug-and-play vacuum units

Compact, ready to connect and easy to maintain: vacuum units with highly efficient separator tank, condenser and heat exchanger

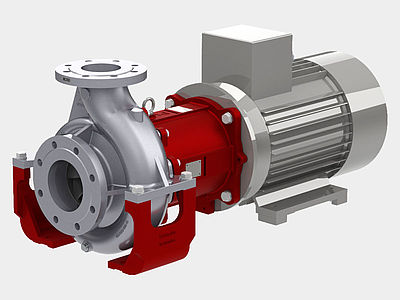

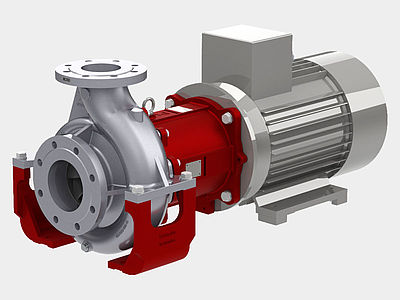

Liquid Ring Vacuum Pumps

Advantages

High quality, reliable with a wide variety of graded pump sizes. SPECK Liquid Ring Vacuum Pumps are suitable for a wide range of industrial applications. Speck offers a broad portfolio of differing robust designs, including those suitable for handling large amounts of water and condensation, water saving versions, low noise pumps, and two-stage versions.

- High-quality, reliable pumps which are suitable for many industrial applications.

- Great variety of graded pump sizes which span a large range of delivery volumes

- Broad portfolio of different designs: Robust standard designs, pumps that are free of dead space, pumps suitable for delivery of water shares, operating water-saving pumps and low-noise, two-stage pumps

Description

SPECK offers both single stage and two stage pumps with and without flap valves, with close-coupled and base plate versions. We engineer our mechanical seals to suit the demands of specific applications where requested, and can provide a double acting seal when required. Certail models, such as our VZ Series are also available with magnetic drive, allieviating the need for a mechanical seal altogether. SPECK offers various build materials such as Copper Alloy Cast Iron and Stainless Steel. Our base plate versions come with the option of material certificates, examination certificates and ATEX II IG IIB+H2 cbk TX, and the close coupled versions with ATEX II 2G cb TX

- Single-stage and two-stage pumps, with and without flap valves

- Close-coupled pumps and base plate pumps

- Mechanical seals, depending on the medium

- Usually with a single mechanical seal, but also available with a double-acting mechanical seal

- VZ model series also with a magnetic coupling

- Various material designs: Copper alloy, grey cast iron and stainless steel

- Base plate pumps with type examination certificate and ATEX (II 1G IIB+H2 cbk TX)

- Close-coupled pumps with ATEX II 2G cb TX

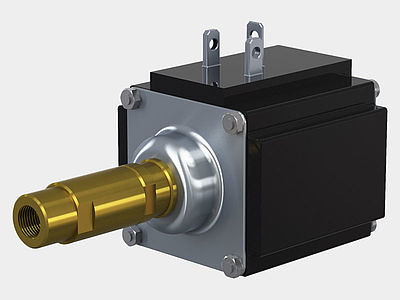

Oscillating Piston Pumps

Advantages

- Simple pumps for high-pressure applications and low flow rates

- Small dimensions

Description

- 50 Hz coil

- Material design in brass

- Tmax

Water up to 60 °C

Gear Pumps

Advantages

- Reliable pumps for high-pressure applications

- Small dimensions

Description

- ZY-MK: Designs with magnetic couplings in stainless steel

- ZY-MM: Designs with canned motor in spheroidal graphite cast iron

- Connection position left/right, threaded

- Tmax

Oil, fuel -40 °C to 80 °C

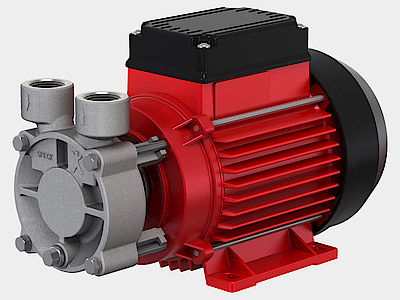

Roller Vane Pumps

Advantages

- Universally deployable pumps for high-pressure applications

- Small dimensions

Description

- DS: Design with mechanical seals

- DS-MK: Design with magnetic coupling

- Connection position top/top, threaded

- Copper alloy or stainless steel designs

- Tmax

Water up to 70 °C

Oil up to 70 °C

Further media upon request - ATEX II 2GD IIC cb TX

Displacement Pumps

Speck exclusively offers constant pumps, i.e. pumps with the same volume for each revolution

- Roller vane pumps (also known as fly pumps)

- Oscillating piston pumps (also known as vibrating diaphragm pumps)

- Gear pumps

Areas of application

- Displacement pumps are (particularly) suitable for very high pressures and/or delivery pressures at very low flow rates

- Suitable for clear or cloudy liquids with no abrasive contamination or solid content

- Suitable for the delivery of gas shares and self-priming

- No return flow of the medium when stopped

Design

- Roller vane pumps and gear pumps with close-coupled design, with magnetic coupling or with mechanical seal

- Wide performance spectrum for roller vane pumps

- Gear pumps with canned motor

Side Channel Pumps

For decades now, Speck has been developing and manufacturing side channel pumps and completely revised the modular system of the SK and ASK model series in 2015.

With a cutting-edge testing area for tests up to 750 m³/h and 400 m, Speck boasts an outstanding framework for research, development and series testing.

Areas of application

- Especially suitable for delivering, filling and draining under difficult physical conditions

- Suitable for clear to lightly contaminated liquids (similar to water) with no abrasive contamination or solid content

- Suitable for the delivery of gas shares and self-priming

- Side channel pumps with an NPSH inducer stage (i.e. with an additional radial impeller) achieve very high NPSH values and can therefore be used with a low suction head. They are very well suited for the delivery of media at temperatures close to boiling point.

- Higher delivery pressures and higher pressures are achieved with multi-stage designs.

Design

- Modular system comprising multi-stage pumps in sections

- Combi-pump with NPSH inducer stage (ASK)

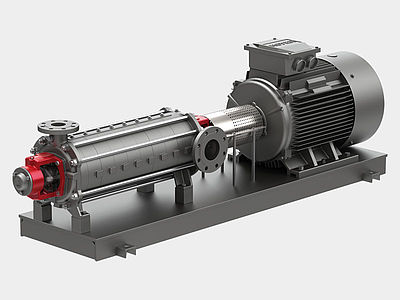

Boiler Feed Pumps

Advantages

- Reliable and universally deployable boiler feed pumps

- Modular system with 4 sizes

Description

- Horizontal pumps with modular design, with mechanical seal or stuffing box packing

- Robust external shaft bearings

- Hydraulically balanced impellers

- Grey cast iron or spheroidal graphite cast iron designs

- PN 40 and PN 63

- Tmax

Water up to 120 °C

Oil up to 120 °C

Further media upon request

Heat Transfer Pumps

Advantages

- High-quality, reliable pumps for low- and high-temperature applications

- Safe in operation, easy to service and robust

Description

- Modular system with 6 model series

- Pumps with mechanical seal or magnetic coupling, with a volute casing or inline casing, with a base plate or bracket

- PN 16, bearing brackets 360 and 470

- Pumps with centreline mounting and/or double volutes

- Spheroidal graphite cast iron and stainless steel designs

- Tmax

Hot water up to 160 °C, up to 180 °C upon request

Heat transfer oils from -100 °C to 350 °C, up to 400 °C upon request - ATEX II 2GD IIC cb TX

Close Coupled Pumps With Ec Motors

Advantages

- High-quality and reliable pumps

- Extremely small dimensions

- SiC sleeve bearings

- Low-noise

- Drive without bearing

Description

- Pumps with magnetic coupling (…-MK), force transmission by outer magnet

- Pumps with canned motor (…-MM), force transmission by motor winding

- Drives with EC motor, 24 V, 12 V upon request

- Designs made from high-quality plastic and stainless steel

- Tmax

Water up to 80 °C

Oil up to 80 °C

Further media upon request

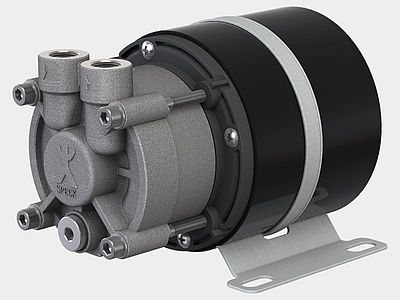

Close Coupled Pumps With Canned Motor

Advantages

- High-quality and reliable pumps

- Extremely small dimensions

- SiC sleeve bearings

- Low-noise

Description

- Force transmission by motor winding

- Connection positions top/top, threaded

Close Coupled Pumps With Ec Motor

Advantages

- High-quality and reliable pumps

- Extremely small dimensions

- SiC sleeve bearings

- Low-noise

- Drive without bearing

Description

- Pumps with magnetic coupling (…-MK), force transmission by outer magnet

- Pumps with canned motor (…-MM), force transmission by motor winding

- Drives with EC motors, 24 V (other voltages upon request)

- Designs in brass, stainless steel and high-quality plastic

- Connection positions top/top, threaded

- Tmax

Water up to 95 °C

Oil up to 90 °C

Further media upon request

Sealless Vertical Pumps

Advantages

- Universally deployable pumps for open circuits

- Sealless and therefore maintenance-free

- Small dimensions

Description

- Vertical single-stage or multi-stage pumps

- Horizontal, threaded pressure connection

- Various submersion depths available

- Robust sleeve bearings

- Material designs:

T-401/601 in stainless steel

TM-201 – TM-701 in copper alloy

T-1001 – T-2001 in copper alloy

- Tmax

Water up to 90 °C

Oil up to 150 °C, up to 200 °C upon request

Further media upon request

Heat Transfer Pumps With Magnetic Coupling

Advantages

- High-quality, robust and reliable pumps for continuous operation

- Leakage-free, low-maintenance and safe in operation

- Hot water version “HT” designed for high system pressures

- Thermal oil version “TOE” impervious to low-boilers in the delivery medium

Description

- Pump shaft made from ceramic, sleeve bearings made from SiC

- Connection position top/top, threaded and SAE flanges

- Normal-priming

- High-quality magnetic couplings

- Stainless steel and spheroidal graphite cast iron designs

- Tmax

Water up to 220 °C

Oil up to 400 °C

Further media upon request - ATEX II 2GD IIC cb TX

Close-coupled Pumps With Magnetic Coupling

Advantages

- High-quality, robust and reliable pumps for continuous operation

- Leakage-free, low-maintenance and safe in operation

Description

- Pump shaft made from ceramic, sleeve bearings made from SiC

- Connection position top/top, threaded and SAE flanges

- Normal-priming

- High-quality magnetic couplings

- Designs in stainless steel, spheroidal graphite cast iron, copper alloy and high-quality plastic

- Tmax

Water up to 180 °C

Oil up to 200 °C

Further media upon request - ATEX II 2GD IIC cb TX (except for EY-MK)

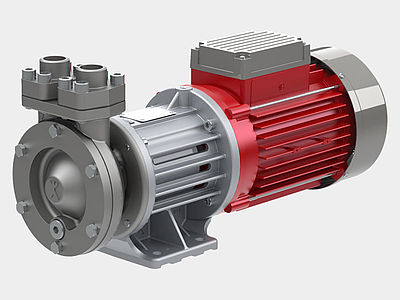

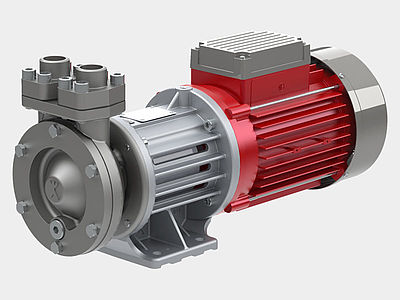

Close-coupled Pumps With Mechanical Seal

Advantages

- High-quality, reliable pumps which are suitable for many industrial applications.

- Great variety of graded pump sizes which span a large range of delivery volumes

- Broad portfolio of different designs: Robust standard designs, pumps that are free of dead space, pumps suitable for delivery of water shares, operating water-saving pumps and low-noise, two-stage pumps

Description

- Single-stage and two-stage pumps, with and without flap valves

- Close-coupled pumps and base plate pumps

- Mechanical seals, depending on the medium

- Usually with a single mechanical seal, but also available with a double-acting mechanical seal

- VZ model series also with a magnetic coupling

- Various material designs: Copper alloy, grey cast iron and stainless steel

Regenerative Turbine Pumps

Advantages

- High-quality, reliable pumps which are suitable for many industrial applications.

- Great variety of graded pump sizes which span a large range of delivery volumes

- Broad portfolio of different designs: Robust standard designs, pumps that are free of dead space, pumps suitable for delivery of water shares, operating water-saving pumps and low-noise, two-stage pumps

Description

- Single-stage and two-stage pumps, with and without flap valves

- Close-coupled pumps and base plate pumps

- Mechanical seals, depending on the medium

- Usually with a single mechanical seal, but also available with a double-acting mechanical seal

- VZ model series also with a magnetic coupling

- Various material designs: Copper alloy, grey cast iron and stainless steel

Liquid Ring Vacuum Pumps

Liquid Ring Vacuum Pump Advantages

High quality, reliable with a wide variety of graded pump sizes. SPECK Liquid Ring Vacuum Pumps are suitable for a wide range of industrial applications. Speck offers a broad portfolio of differing robust designs, including those suitable for handling large amounts of water and condensation, water saving versions, low noise pumps, and two-stage versions.

- High-quality, reliable pumps which are suitable for many industrial applications.

- Great variety of graded pump sizes which span a large range of delivery volumes

- Broad portfolio of different designs: Robust standard designs, pumps that are free of dead space, pumps suitable for delivery of water shares, operating water-saving pumps and low-noise, two-stage pumps

Liquid Ring Vacuum Pump Design

SPECK offers both single stage and two stage pumps with and without flap valves, with close-coupled and base plate versions. We engineer our mechanical seals to suit the demands of specific applications where requested, and can provide a double acting seal when required. Certail models, such as our VZ Series are also available with magnetic drive, allieviating the need for a mechanical seal altogether. SPECK offers various build materials such as Copper Alloy Cast Iron and Stainless Steel. Our base plate versions come with the option of material certificates, examination certificates and ATEX II IG IIB+H2 cbk TX, and the close coupled versions with ATEX II 2G cb TX.

- Single-stage and two-stage pumps, with and without flap valves

- Close-coupled pumps and base plate pumps

- Mechanical seals, depending on the medium

- Usually with a single mechanical seal, but also available with a double-acting mechanical seal

- VZ model series also with a magnetic coupling

- Various material designs: Copper alloy, grey cast iron and stainless steel

Oil Filled Rotary Vane Pumps

SV series single-stage oil-filled rotary vane vacuum pump is a reliable, durable, economical and adaptable range of vacuum pumps.

In the circular pump body, is an air suction valve and exhaust valve (stator). The vanes are equipped with an eccentric slot in the rotor. The vane blades divide the pump chamber into three parts. The volume of the pump chamber keeps changing periodically as the rotor rotates to finish the process of gas suction, compression and elimination.

Dry Screw Vacuum Pumps

LG series dry screw vacuum pumps can manage both condensable vapours and some solids with no residue. They offer a number of advantages over the traditional vacuum pump designs. There’s is no oil or water in contact with the process vapours, so therefore they are considered environmentally friendly.

Two Stage Oil Sealed Pumps

2XZ series direct-driven rotary vane vacuum pump is one of the main types used for pumping gas from sealed vessels. It not only can be used alone, but also can be a backing pump for booster pumps, diffusion pumps, turbo molecular pumps and titanium pumps.

It can be used for electric vacuum device manufacturing, thermos manufacturing, vacuum welding, printing, plastic, refrigeration equipment repair and instrument repair facilities, etc.